Everything we brought you in XO4 was great. The industry thought it couldn't get better. Our competition thought it couldn't get better. However, We wanted to push the bar higher. XO4 was a great start on how to improve ther aftermarket screen assemblies however we wanted to continue and bring more added benefits!As the market is having better screen assemblies coming out. We wanted to perfect it as much as possible and bring some additional features.

Perfecting the black color has been a big challenge. As the polarizer has a lot to do with achieving true black tones. However, over-darkening the polarizer can bring all the other colors to a darker spectrum. After extensive research, we found out about a secret polarizer only used by a select few. This polarizer has not typically been used in aftermarket screen assemblies. After a first glance using this new polarizer in one of our screens, we knew we had landed on gold. We are proud of the true black in XO5 Technology!

Oleophobic coating is a must now. However, electroplate oleophobic coating is still new to China. We tried implementing this technology on XO4 and the feel was outstanding! Sadly, when machines bake the coating on as part of the manufacturing process, the oil forms an uneven surface affecting the application of tempered glass. We invested in higher quality machines, and better manufacturing processes to ensure this would never happen again. XO5 screens have a smoother coating, much better finish, and a 12% increase in friction over its predecessor.

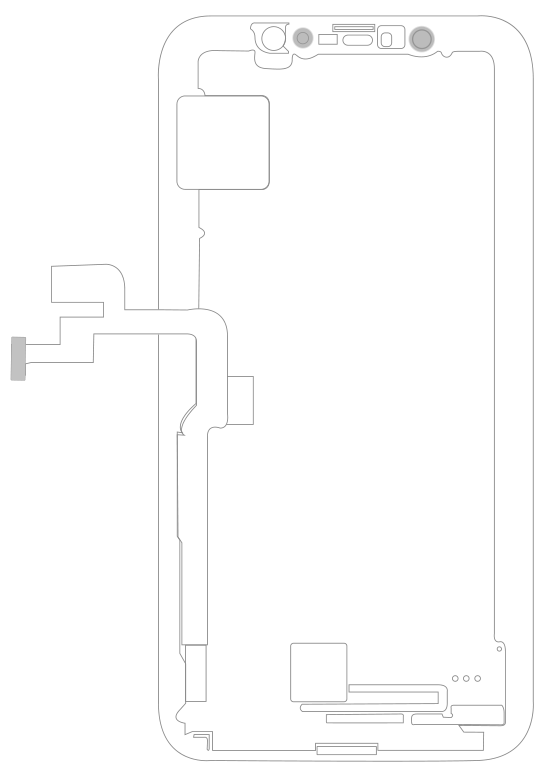

Force touch is a very important feature for screens, and at this point, it has still not been addressed. Many other aftermarket screens will use a “copy 3D Touch”. However, copy 3D touch won’t work on tables and other surfaces, and it is not as responsive as the OEM Equivalent. XO5 wanted to push it a bit further by not only improving the overall experience of 3D touch but focusing on the small things like side 3D that the manufacturers always overlook. We designed our own 3D touch panel to enhance this experience for our customers.

With the launch of the iPhone 8 and 8 Plus, Apple enabled an interesting feature called "True Tone”. This feature left out all aftermarket screens from being able to achieve the activation of this feature after any screen replacement. Unfortunately, aftermarket screens lack an EEPROM Chip, therefore serial numbers cannot be transferred over… Until NOW! True Tone Functionality for iPhone 8 & 8 Plus screen assemblies will have the ability to be programmed to have the True Tone Functionality available.

China copy LCDs lack the capability to refresh the pixels as fast as OEMs. We saw this as a major drawback in the market. We knew that this had to be one of our top priorities. For a long time, repair shops have been offering an inferior screen and not knowing what to say when their customers ask about the screen lag. We decided to take on the task, rather than ignoring the issue as mostly all other manufacturers. XO5 technology will give you an exceptionally close experience to an OEM screen. In Maui words… “You’re welcome”.

This is an Aftermarket first! Backlight technology has grown tremendously. However, we are still housing it in a simple steel enclosure, which leaks about 8-9% of the light due to missing seals in aftermarket screens. We are adding the 2-layer backlight seals to trap as much light within the backlight enclosure and channel it to the front panel. This means better colors, lower temperatures, and almost close to zero light leaks. The other aftermarket manufacturers will follow suit but XO5 technology is a true leader in aftermarket screens.

We all know about that annoying yellow spot on the screens. It happens when the screen is not perfectly aligned for the IC to fit right on top of the loudspeaker. We asked software and hardware companies over and over to help us solve this, and they told us that China couldn’t help us in this process. We had to look outside and elsewhere. Our engineers reached out to Taiwan, the semiconductor and IC chip capital. We found a small factory that solely works on driver ICs for LCD panels. This company introduced us to his latest IC chip, condensed in a fourth of the size, with the same capabilities as the ones currently found on OEM screens. This is something the industry has been waiting for a long time, and you will be able to have this technology in XO5 Technology.

No one cares as much as us! So we wanted to make XO5 screens as best as we possibly could. We took into consideration all the tiny things that we could improve on like the front camera cushion, light diffusers, steel plate with heat shields, waterproofing the IC plate, using a 2 layer ear mesh, Kapton tape, taped down home button connectors and many more often overlooked features. We know you don’t need these, but why not offer your customers the best?

Sure, we can continue putting the same FPC connectors as the rest of the world... But WHY? XO5 sees a flaw in this minor problem. After installing and uninstalling the screen a few times with the copy FPC connectors, the pins start to open and cause poor connectivity. XO5 Technology only uses OEM Grade FPCs to achieve the manufacturer’s standards.

XO5 LCDs was designed with keeping the OEM specs in mind. XO5 is still a TFT panel, meaning that getting to the OEM quality is not going to be possible. However, we have gotten quite closer and even better. XO5 is best experienced when installing into a device and comparing the difference to what the regular suppliers and China is offering. This graph will show where XO5 has excelled more than ever and the standard China copy LCDs stand when comparing them to OEM Displays.

As continued efforts to bring better improvements with the predecessor of X04, we wanted to push the bar further and bring you more knowing that there will always be more advancement. Rest assured, your answers were heard and all the key features asked were addressed and improved.

IPHONE 8 plus

IPHONE 8 plus IPHONE 8

IPHONE 8 IPHONE 7 plus

IPHONE 7 plus IPHONE 7

IPHONE 7 IPHONE 6s plus

IPHONE 6s plus IPHONE 6s

IPHONE 6s IPHONE 6 plus

IPHONE 6 plus IPHONE 6

IPHONE 6